Category: News

With over 40 years in business WMH is always eager to push the bounds of possibility and develop new solutions to problems through bespoke design. One recent project has seen WMH design and build a series of mini conveyors with the shortest coming in at under 4 inches in length.

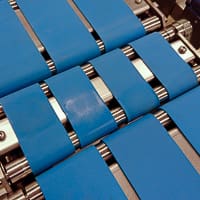

Whilst the mini conveyors are grouped together to form part of a complex system each of the individual units is fully formed, self-contained conveyors which could stand alone; complete with end rollers, drive unit and tension adjusters.

When assembled into the finished machine the mini conveyors use servo drive technology to collate and position a random flow of products into equally spaced and accurately positioned units. The smart collation creates batches of product which go on for further processing together.

Manufactured to WMH’s hygiene and wash-down standards the smallest conveyor WMH has ever built has an end to end length of just 100mm and is fitted with stainless steel crowned end rollers, manufactured in-house by WMH’s machine shop. The conveyor has an underslung servo drive motor coupled to the drive roller via a toothed belt and pulleys.

Due to manufacturing restrictions of the belt, the conveyor had to be fitted with 4 off 50mm wide belts to give the required product carrying width.

“This is a bit of a novel design to solve a particular problem” said a spokesman for WMH “the design principles developed for this project though will be carried through to other applications in the future”.