Designed to meet your specific production requirements

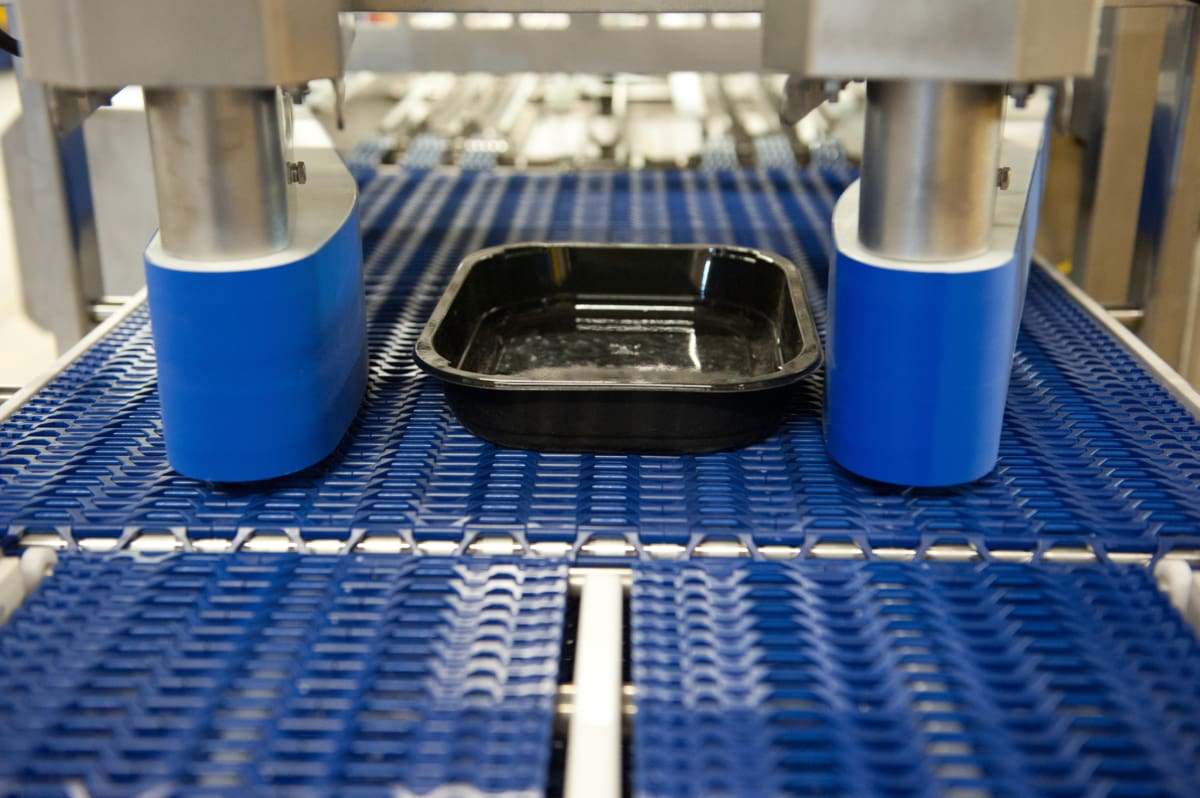

WMH ready meal assembly lines are designed to offer flexible assembly of your ready meals whether you require manual operator positions, fully automated depositor locations or a combination of both WMH can provide you with a line that works for you.

WMH Ready meal assembly lines are:

- Designed to fit your range of tray sizes

- Single or twin lane configuration

- Continuous or indexing operation

- Fitted with electrical and pneumatic service outlets

- Outfeed lane merging option

- Touch-screen menu driven operator control

Going the extra mile

WMH understands the demands of a high care environment and designs all machines to be washed down and where possible minimises the areas where build-up of debris can occur, with sloping surfaces and spacing off of bearings and joining brackets and support frames.

The success of your project lies in the communication between the line and ancillary equipment. WMH goes that extra mile to ensure your line integrates successfully with upstream and downstream process equipment and will work with other suppliers to ensure a seamless production line.

For more information or to discuss a specific requirement please give one of our sales engineers a call on 01579 383788 or email enquiries@wmh-uk-ltd.com.

Key features

Continuous or Indexed motion | Single point guide width adjustment | Hygienic robust design | Single or twin lane operation | 2 to 1 lane merge function | Variable product pitch | Integrated service connection points

View our equipment in action