Category: News

The end of line packing stage of many production lines is often cramped and chaotic as people, pallets and product jostle for space in less-than-ideal conditions. WMH have helped many clients over the years to create order from chaos by installing ergonomic packing stations that ensure the comfort of the packers.

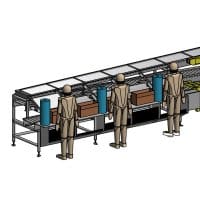

WMH are currently building a new packing system for a local pasty bakery which will streamline the packing of their premium pasties. The system enables up to five packers to pack product from baking trays into cartons in comfort with minimal lifting and twisting. Each packer is presented with a tray of product to be unloaded and packed into ready erected cartons. Once filled each carton is taken away to be automatically taped, leaving the packer free to pack their next box.

Product and boxes are presented to the operators on multiple-levels to minimise twisting and heavy lifting. This multi-level packing approach is similar to previous end of line packing stations developed by WMH.

“The multi-level packing approach is one that we have used for a wide range of packing situations, we find that packers can work more efficiently when all that elements needed for packing are easily to hand” Said a spokesman for WMH.

For more information on WMH packing please visit the High Care End of Line Packing page or call 01579 383788 to speak to one of our sales engineers.