Developed high-tech handling solutions

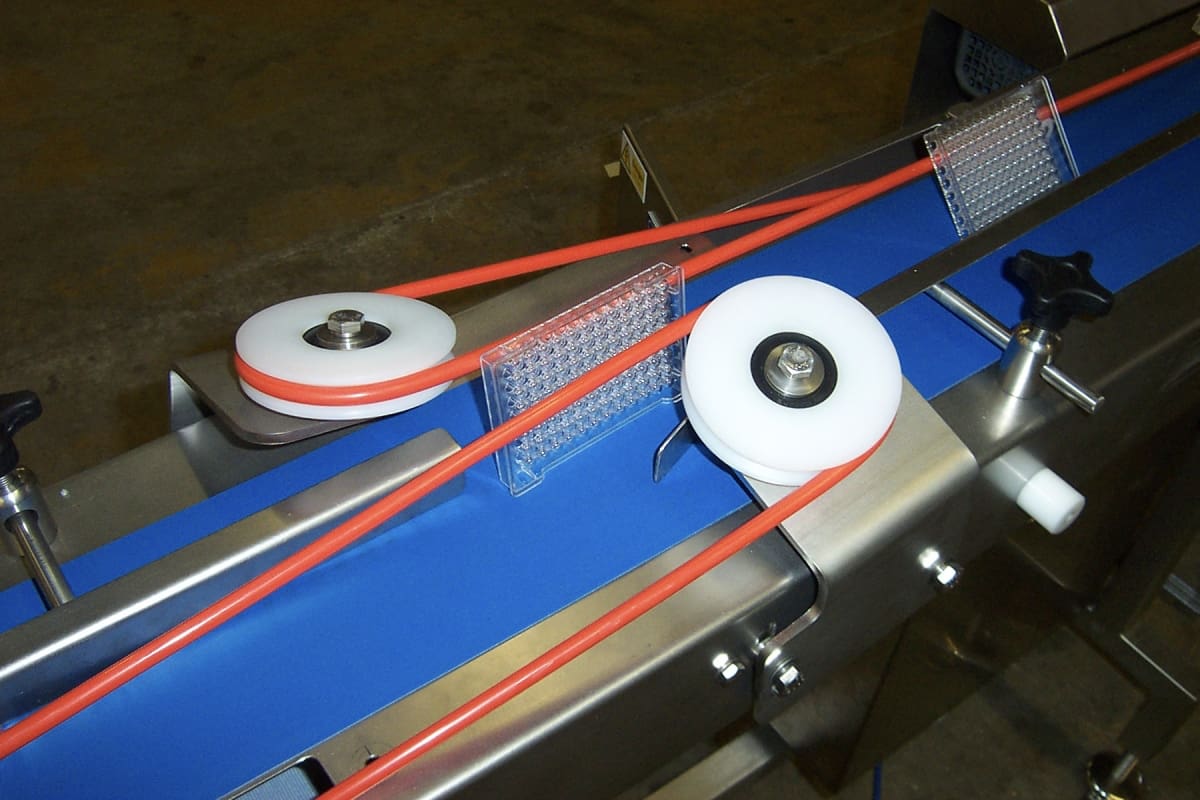

Innovative Solutions for Pharmaceutical Applications WMH specialises in developing cutting-edge handling solutions tailored for diverse pharmaceutical applications. As a trusted design and build company, we collaborate closely with clients to create bespoke machinery that addresses specific and specialised handling requirements within the pharmaceutical industry.

At WMH, we uphold our commitment to delivering high-quality equipment, renowned for its durability, hygienic design, and flexibility to adapt to evolving production needs. Just like our food handling machinery, our solutions for pharmaceutical applications meet the highest standards of reliability and adaptability.

We recognise the stringent demands of clean room environments and design every machine with cleanability in mind. Our engineering minimises debris accumulation by incorporating sloped surfaces, spaced-off bearings, and carefully positioned brackets and support frames, ensuring optimal hygiene and efficiency.

Example Projects

Some of the projects WMH has been involved in include:

- Robotic pick and place of individual medical devices

- Collation of medical devices into groups for packing

- Robotic packing of products into boxes

- Multi-tier tray storage and holding system

- Robotic spraying and coating of test tubes

- Pneumatic conveying systems

- Weigh hoppers

- Tumbling and coating equipment

- Pack turning

- Sample tray inverting

- Product buffering

- Line automation and control systems

For more information or to discuss a specific requirement please give one of our sales engineers a call on 01579 383788 or email enquiries@wmh-uk-ltd.com

Typical applications

Robotic dosing systems | Multi-stage robotic collation of medical devices | Weigh hoppers, to deliver batches of products | In-line holding of product for checking/verification | Inline storage and holding system | Aligning blister packs for flow wrapping | Pellet coating

View our equipment in action