Developed for a range of product formats

WMH provides spiral freezer and chiller loading and unloading systems to large commercial bakeries. Systems are designed to handle many formats of product from chilling of freshly baked goods to freezing of ice cream.

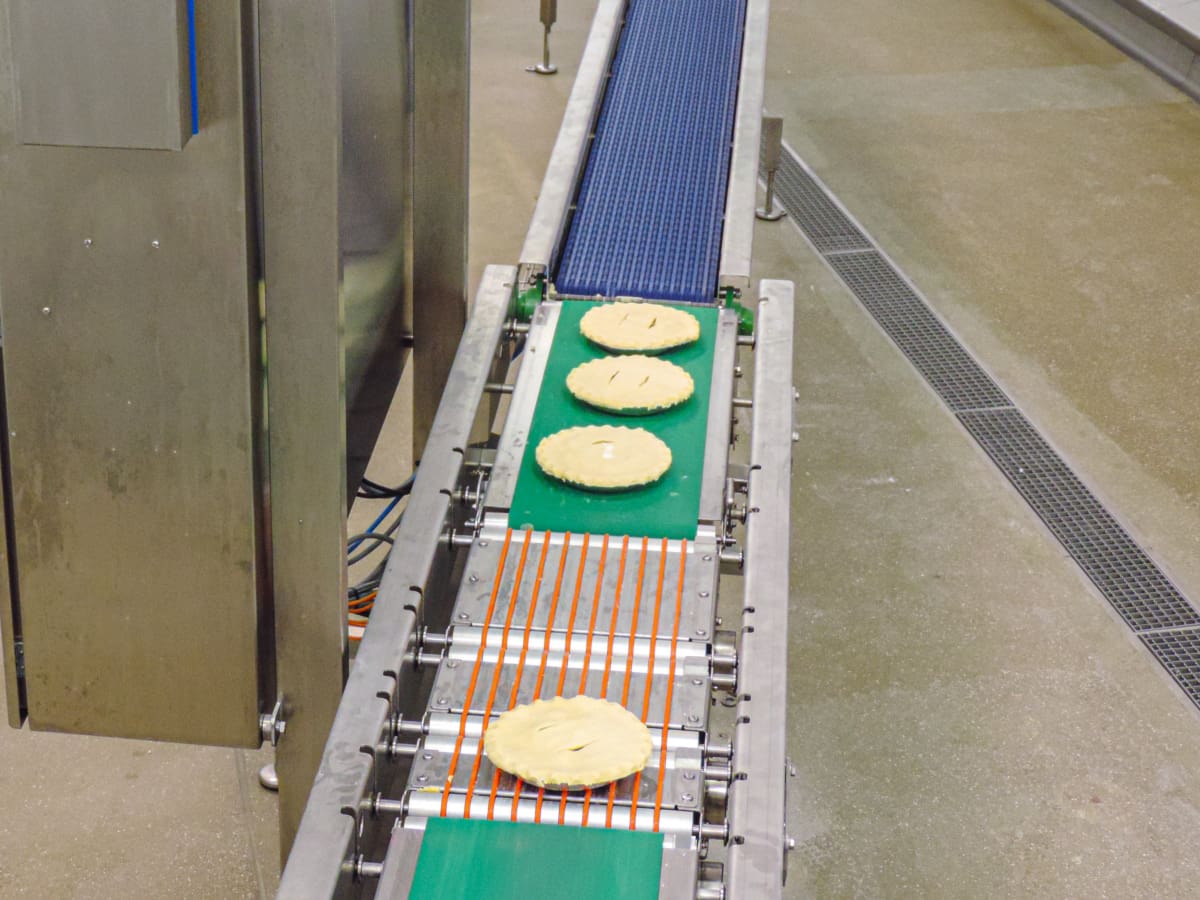

Our solutions seamlessly convey your products from oven to freezer and or freezer to packing line. WMH takes care to gently collate or lane products across the chiller belt. This ensures your line runs efficiently with optimum product loading. Maintaining the maximum throughput for your production line.

Seamless Integration

Our chiller and freezer unloading systems ensure a seamless transition of product along your line. High level outfeeds are designed to minimise the risk to products by bringing products down to low level as soon as possible, but also maintaining shallow decline angles to ensure products are handled in a controlled manner.

WMH works closely with the supplier of your freezer or chiller to develop a solution that best suits your product and production requirements.

Key features

Areas where WMH can help:

- Transfer from assembly line

- Laning and collation

- Mesh belt oven loading

- Steel band oven loading

- Platten oven loading

- Integration with depositing

- Post cooking product alignment

- Laning and collation for further processing

With 40-years working in the food industry WMH understands the demands of a high care production environment and designs all machines to be washed down and where possible minimises the areas where build-up of debris can occur, with sloping surfaces and spacing off of bearings and joining brackets and support frames.

For more information or to discuss a specific requirement please give one of our sales engineers a call on 01579 383788 or email enquiries@wmh-uk-ltd.com.

Typical products

Quiche | Sweet & Savoury Pies | Cakes | Yorkshire Puddings | Sausage Rolls & Pasties | Ready Meals

View our equipment in action